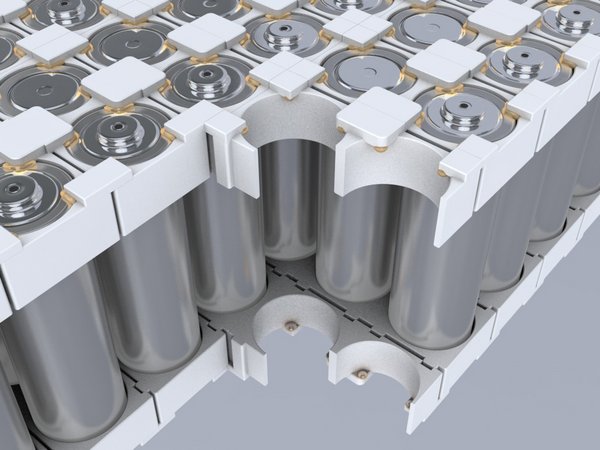

SHANGHAI, March 13, 2020 /PRNewswire/ -- As automotive electrification continues to evolve, powerful lithium-ion (li-ion) battery architectures are at the center of discussions around electric vehicles. While battery system designs vary by manufacturer, the joint performance objectives for all automotive battery technologies are longer lifetime, operational safety, cost efficiency and reliability. In their most recent collaboration, Henkel and Covestro developed a solution enabling the efficient fixation of cylindrical li-ion battery cells inside a plastic cell holder. The solution is based on a UV-curing adhesive from Henkel and a UV-transparent polycarbonate blend from Covestro.

With a strong consumer push to reduce electric vehicle prices, large-scale and cost-efficient li-ion battery cell assembly is a prerequisite for every automotive OEM. As such, Henkel's Loctite AA 3963 battery assembly adhesives and Covestro's UV transparent polycarbonate blend Bayblend® were developed for compatibility with high-volume automated dispensing techniques and offer flexible and fast cure mechanisms. The acrylic adhesive was formulated for use with the cell holder, which is constructed of a special flame-retardant plastic. It provides strong adhesion to the substrate material and offers production adaptability through long open times and short cure cycles.

Efficient and flexible production

"High-volume manufacturing operations with short cycle times and process flexibility are essential," explains Frank Kerstan, Head of e-Mobility Europe at Henkel. "The Loctite OEM-approved adhesive designed to secure cylindrical li-ion cells into a carrier is a one-part, cure-on-demand formulation. After high-speed dispensing, the material's long open time inherently builds adaptability into the process by allowing for any unexpected production interruption. Once all cells are placed into the adhesive and secured in the holder, curing is activated with ultra-violet (UV) light and takes place in less than five seconds." This is a major advantage over conventional manufacturing where curing times can range from several minutes to hours, thus requiring additional storage capacity for parts.

The cell holders are manufactured from Covestro's PC+ABS blend Bayblend® FR3040 EV. With a thickness of only one millimeter, the plastic already meets category V-0 of the Underwriters Laboratories' UL94 flammability rating but shows good permeability for UV radiation in the wavelength range above 380 nanometers.

"The material allows us to construct dimensionally stable parts that are necessary for automated mass assembly," says Steven Daelemans, Market Development Manager E-Mobility in the Polycarbonates segment at Covestro. "Together with the fast-curing capability of the Loctite adhesives, this material combination delivers an innovative approach to large-scale cylindrical li-ion battery module production."

Loctite is a registered trademark of Henkel and/or its affiliates in Germany and elsewhere.

About Henkel

Henkel operates globally with a well-balanced and diversified portfolio. The company holds leading positions with its three business units in both industrial and consumer businesses thanks to strong brands, innovations and technologies. Henkel Adhesive Technologies is the global leader in the adhesives market – across all industry segments worldwide. In its Laundry & Home Care and Beauty Care businesses, Henkel holds leading positions in many markets and categories around the world. Founded in 1876, Henkel looks back on more than 140 years of success. In 2018, Henkel reported sales of around 20 billion euros and adjusted operating profit of around 3.5 billion euros. Henkel employs around 53,000 people globally – a passionate and highly diverse team, united by a strong company culture, a common purpose to create sustainable value, and shared values. As a recognized leader in sustainability, Henkel holds top positions in many international indices and rankings. Henkel's preferred shares are listed in the German stock index DAX. For more information, please visit www.henkel.com.

About Covestro

With 2019 sales of EUR 12.4 billion, Covestro is among the world's largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, construction, wood processing and furniture, and electrical and electronics industries. Other sectors include sports and leisure, cosmetics, health and the chemical industry itself. Covestro has 30 production sites worldwide and employs approximately 17,200 people (calculated as full-time equivalents) at the end of 2019.

Photo - https://photos.prnasia.com/prnh/20200313/2749201-1-a?lang=0

Photo - https://photos.prnasia.com/prnh/20200313/2749201-1-b?lang=0