|

China is leading the way especially in industrial AI

LUDWIGSBURG, Germany, March 19, 2024 /PRNewswire/ -- The digitalization of industry is continuing to advance worldwide, despite ongoing difficult conditions. That is a key finding of the Industry 4.0 Barometer 2024 published by MHP in conjunction with LMU Munich. The study surveyed 856 representatives from industrial companies in China (248), the USA (204), the DACH region (203) and the UK (201).

Regional differences are clear

When comparing individual regions, significant differences are apparent. In China, 66 percent of participants said they partially or fully use tracking technology, compared to 64 percent in the US and only 36 percent in the DACH region. The differences are even more stark when it comes to digital twins. In China, 72 percent of the companies surveyed partially or fully use a digital twin of their entire logistics operations to map process and status data. This figure is 43 percent in the US, 29 percent in the UK and 25 percent in the DACH region. And while 41 percent of respondents in the DACH region said they did not use autonomous machines or robots, 28 percent said this in the US and only 2 percent in China.

Prof. Christina Reich of FOM University and a manager at MHP said: "Essentially, this is the picture for all Industry 4.0 aspects: China leads by a considerable margin – meanwhile, even the US is lagging a good way behind almost everywhere. The UK then generally follows in third place. It is mostly the DACH region that has the biggest need to catch up."

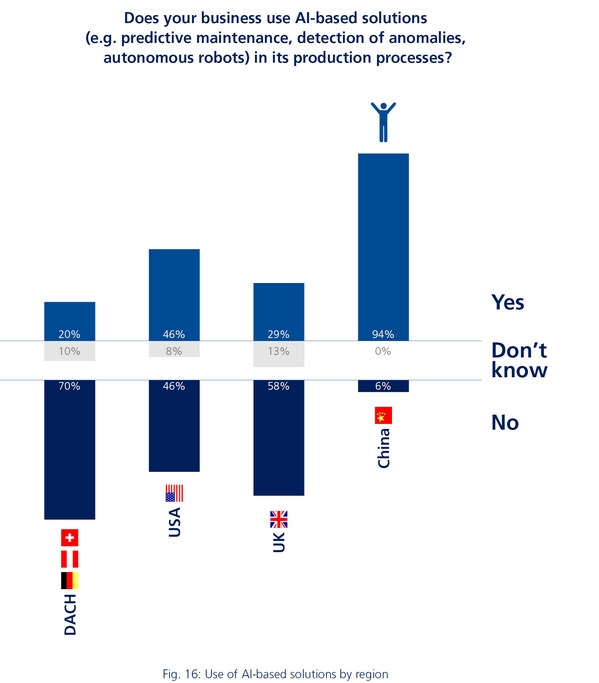

This is also the case for industrial AI – this year's focus of the study. In China, 94 percent of the companies surveyed already use AI-based solutions in their manufacturing processes. That is more than twice as many companies as in the US, which follows with 46 percent. In the UK, 29 percent of respondents say they used AI-based solutions, while the figure in the DACH region is 20 percent. This divergence is particularly noteworthy because around 60 percent of respondents rate the impact of AI in manufacturing processes as fundamental, very high or high in the coming years. A key reason for the clear differences is the shortage of qualified employees.