GUIYANG, China, April 21, 2023 /PRNewswire/ -- A news report from Huanqiu.com:

In the morning, when I entered the production workshop at Guizhou Tire, I saw a staff member first scan the tires with their mobile phone, check the production plan of the day with just a click of the mouse, and start the AGV trolley for automatic carriage. That is how their work day starts. It is hard to imagine this happens at the largest manufacturing company in Guiyang.

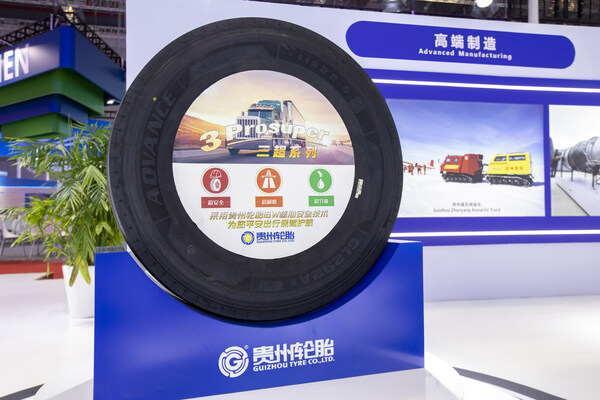

Guizhou tires displayed at the 5th China International Import Expo Special Zone. (Source icphoto.cn)

"This is a tire liner flow card, which our staff member just scanned. Scan it with our APP for Guizhou Tire, and you see all the information about the part, including production time, quantity, production line number, and location. On the card, there is a barcode. Scan it, and you know in which process the product is. You can know everything at a glance," explained Yuan Yi, director of the Production Department at Guizhou Tire.

Currently, the system has become a typical link at Guizhou Tire in its deep integration of "Big Data+" and industry. However, this merely serves as an epitome of the company's endeavor to rely on "Big Data+" to empower their intelligent manufacturing. To realize new industrialization, it is necessary to transform development from factor-driven to innovation-driven, which calls for the support of the "Guizhou Industrial Cloud" platform.

In 2020, Guizhou Tire made an investment of over 200 million yuan in research and development, relying on the big data analysis system on Guizhou Industrial Cloud to collect customer needs, market information, historical test data, etc., for carrying out model design and developing marketable tire products.

"As a platform based on China's first big data pilot zone in Guizhou, Guizhou Industrial Cloud is dedicated to promoting the transformation and upgrading of local companies using the new information technology. It is also among the 7+N clouds of Guizhou's big data pilot projects," according to Yang Lingyun, chairman of Guizhou CASICloud Tech Co., Ltd., the builder and operator of Guizhou Industrial Cloud Platform. Guizhou Industrial Cloud Platform can effectively improve company efficiency, reduce costs, shorten the R&D cycle, and meet the needs for digitalization, networking, intelligence, and cloud in industrial players through cloud resources, cloud software, and intelligent manufacturing solutions with "end, network, and cloud" connectivity.

"Today, Guizhou Industrial Cloud has become a major driving force and platform for enhancing the deep integration of big data and the real economy in Guizhou, making the platform a successful example for promoting the transformation of the real economy," Yang Lingyun said.

At Guizhou Yaguang Electronic Technology Co., Ltd., thanks to Guizhou Industrial Cloud, the intelligence-empowered production line has seen a boost of 58% in output, 33% in excellent product rate, and 15% in economic benefits, with a decline of 46% in site area and 68% in the production line staffing (per team). AVIC Liyuan Hydraulic Co., Ltd. has used the platform for procurement and realized the integrated and order-driven production and procurement, under which its number of procurement staff reduced by 50% and the timely delivery rate increased by 90%. HICCOM Precision has also undergone a shift from Industry 2.0 to Industry 3.0 by applying the wide array of functional modules on Guizhou Industrial Cloud, which laid a solid foundation for its entering the international market.

"We want to help industrial companies realize digital transformation so that they can transform and upgrade in the information age with 'the cloud'," according to Yang Lingyun. Advanced technologies such as cloud computing and the Internet of Things can not only help a company connect its industrial comprehensive factor data but also optimize its allocation of resources with better quality and efficiency through intelligent production.

Up to now, the number of registered users on the Guizhou Industrial Internet Platform has exceeded 170,000, pooling 204 industrial software and 2308 industrial apps while connecting 14,178 pieces of main production equipment and nearly 3,000 companies on the cloud.